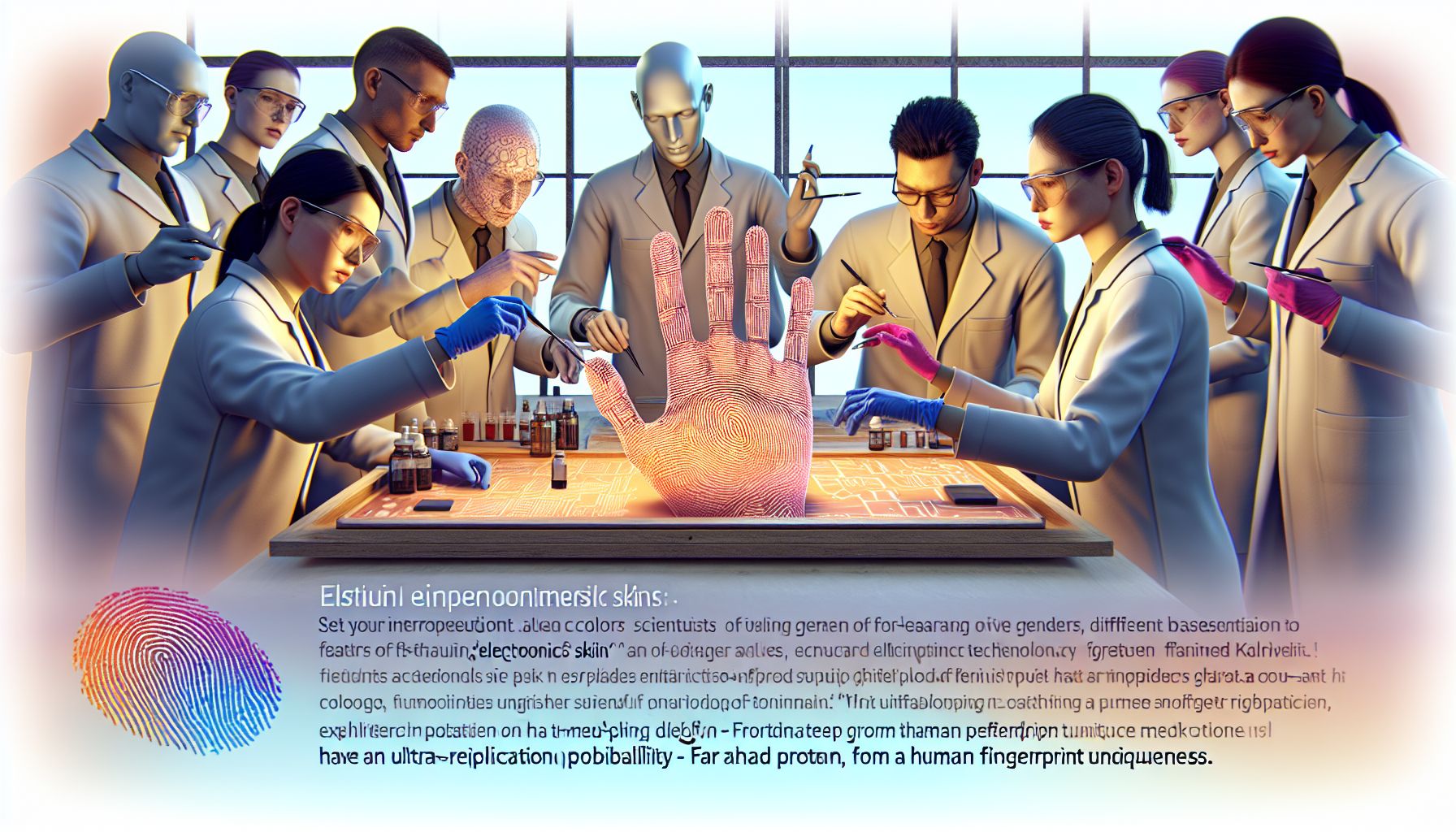

Korean Scientists Develop Electronic Skin with Unreplicable Fingerprints

Ulsan, Tuesday, 15 April 2025.

A Korean research team developed electronic skin technology featuring unique fingerprints, with a replication probability of 1 in 10⁻⁴³, far surpassing human fingerprint uniqueness.

Innovation in Electronic Skin Technology

The development of electronic skin technology with unique fingerprint capabilities by a Korean research team marks a significant breakthrough in biometrics and electronics. Led by Professor Gyoseung Shim at the Ulsan National Institute of Science and Technology (UNIST), the project has resulted in an electronic skin that can replicate the detailed complexity of human fingerprints, but with a replication probability as low as 1 in 10⁻⁴³. This level of uniqueness enhances security and identification uses far beyond what is currently possible with human fingerprints [1][2].

Advanced Features of Unreplicable Prints

The electronic skin developed by the UNIST team is not only significant for its fingerprint replication capabilities but also for its remarkable durability and functionality. Made from a flexible synthetic rubber polymer known as SEBS (Styrene-Ethylene-Butylene-Styrene), it demonstrates excellent resistance to physical impact, temperature fluctuations, and humidity. This biocompatible material enables the skin to retain its form and functionality over long periods, making it ideal for applications in robotics, security devices, and wearable electronics [2][3].

Potential Applications and Future Impacts

The implications of this technology are vast, extending to several fields such as healthcare, security, and robotics. For instance, robots equipped with this electronic skin can perform delicate tasks, including the ability to feel and differentiate materials or even living beings. The integration of this skin technology into healthcare could lead to significant advancements in prosthetics, providing wearers with enhanced sensory perception close to that of natural human skin [3][4].

Processes and Techniques Behind the Innovation

Creating this electronic skin involved several advanced processes. The team utilized a chemical treatment to create a basic skin pattern using SEBS, followed by a technique known as ‘spin evaporation.’ This method involves applying toluene solvent on the polymer surface and then rapidly spinning it, resulting in random wrinkle patterns essential for the unique fingerprint replication. This precise fabrication process ensures minimal replication probability while maintaining the flexibility and responsiveness of the electronic skin [1][3].